Categories

Tags

Archives

The Accessible Of High Pressure Grease Fitting

-

As we write this the snow is melting in New Hampshire everyone is getting their machines out and ready for the spring.

CLEAN

The best way to avoid clogged High Pressure Grease Fitting is to keep them clean, and greased regularly. While it may be impossible to keep a manure spreaders or baler clean, Grease Fitting Caps go a long way towards keeping dirt and grime out of your grease Zerks.

FUNCTIONAL

If there's one thing more frustrating than trying to grease sticky Zerks, it's having to replace them. If you broke off the heads of Zerk fittings using an old traditional grease coupler, the right tools can make it easy to replace.

We sell four-way tools in two sizes that give you an easy way to extract broken fittings, rethread new fittings, and retap stripped holes. If you need new Zerks, we have those too.

ACCESSIBLE

It's no secret that many machines get put together without a thought to where the grease Zerks are placed. This means reaching down into impossibly tight spots, around corners, through shields, or even disassembling covers just to reach them. Our relocation kits replace the grease fitting with an elbow adaptor and a length of hose with a grease Zerk on the end. You can now decide exactly where you want the grease Zerk to be and stop fighting to get your grease gun down into those tight spots. Learn more on the product page.

On older Grease Couplers, a clogged fitting can create back pressure in the hose and coupler, making it hard to depress the thumb lever and remove the coupler. We suggest applying some light pressure to the thumb lever with a pair of pliers - it should pop right off. Resist the urge to twist or jerk the coupler to the side, because this can damage the seal.

Sometimes, a clogged fitting needs some time and work to really work itself out. They're the toughest tool we've found for clearing clogged fittings, and they truly get the job done. Load up a Grease Buster with Liquid Wrench, Mineral spirits, or any penetrating oil, and tap the piston a few times. As tempting as it may be, don't smash the thing with a hammer - the point is to use vibration to get the oil in there and slowly break up the clog, not to blast it through your bearings. We also sell a pneumatic piston for the Shop Size Grease Buster that is compatible with pneumatic hammers.

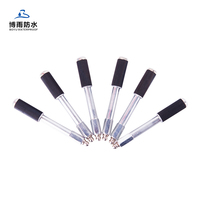

We are a waterproof company, offers Brass Injection Packers,Injection Pump,Injection Packers, Polyurethane injection grouting and so on, Please contact us anytime.