Categories

Tags

-

#CNC Machining

#Custom Cnc Machining

#Cnc Machining Process

#CNC Machining Parts

#Cnc Machining Center

#Liquid Cold Plate

#CNC Milling Services

#high-precision CNC machining

#Type C Connector Manufacturer

#TYPE-C connector

#Injection Molding

#Injection Tooling Fabrication

#Type C connector

#usb 3.0 connector

Archives

Liquid Cold Plate Solutions

-

Liquid Cold Plate ManufacturerIn China — Kingka

Kingka is a professional custom liquid cold plate manufacturer in the cooling system field, provide thermal management system solutions for new energy vehicles and power electronic products. Our technical team has many years of experience in R&D and production of liquid cold plate heat sinks.

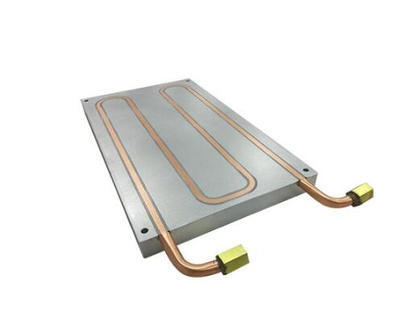

Liquid Cold Plate with Copper Tube

Our company Hi-Contact technology optimizes the contact area liquid tubes have with a cooling surface to provide the best possible liquid cold plate thermal performance. Our patented geometry used in these designs ensures the most tube-to-plate and tube-to-device contact possible to minimize interface resistance between all contact surfaces. To further increase performance, a thermal epoxy is applied to the tube/plate joint to provide a gap-free thermal interface between the tube and cold plate.

Liquid Cold Plate with Friction Stir Welding Process

Friction stir welding liquid cold plate can be used extrusion techniques, which are used to form the flow passages of the cold plate directly and the flow passages are connected through by machining any blockage. The assembly is sealed by the friction welding technique with a high production throughput and low cost. This technique is not suitable for applications with higher power density or too many screw holes on the surface since this will create constraints for the flow passages. The main applications include the cooling of power batteries, heating devices, and integrated cooling products such as standard power modules. And the dimensions and routes of the internal passages can be designed with greater freedom. This is suitable for thermal management products with a larger power density, irregular heat source layouts within a limited space. The main applications include wind power converters, electric motor controllers, lasers, special power supplies, and supercomputers and ser.