Categories

Tags

Archives

Epoxy versus Polyurethane Injection Grouting Crack

-

When you need to repair a crack in a concrete structure — such as a foundation or wall — from the inside (negative side) of the structure, there are typically two injection techniques and corresponding product technologies that you need to consider — epoxy resin injection and polyurethane chemical grout injection.

Epoxy injection is typically performed on dry substrates versus Polyurethane injection grouting that works very well on wet and actively leaking substrates. Epoxy injection is the preferred method where structural crack repair is desired.

Polyurethane injection is performed to seal active leaks, prevent moisture migration and to protect structures from corrosion and water related decay. Polyurethane injection technology is superior in most wet and actively leaking environments.

There is an injection solution to most concrete crack related problems. But, there is no one-size-fits-all solution.

Let us compare some of the main characteristics of each type of crack injection, outlining their strengths and their recommended range of applications.

Injection Repair Objectives | Conditions & Results

Does your crack impact the structure?

Do you need to restore structural strength to the structure?

Does the crack carry water?

Is the crack actively leaking?

Do you need to protect the structure from water ingress and water damages?

Comparison of the characteristics of epoxy and polyurethane

Epoxies and polyurethanes are chemical resins with different reaction profiles and physical properties.

Epoxy is a strong adhesive or glue that does essentially not expand. While curing epoxy creates a strong bond with the concrete substrate and ultimately provides a repair of high compressive and tensile strength properties.

Epoxy is a two component system, one component is the epoxy resin and the second is the hardener. The components are blended in the static mixer of the injection pump applicator immediately before crack injection. Injection epoxies cure chemically within a specified time and harden further over days and weeks.

Polyurethane injection foam is primarily a water activated sealant or leak-seal grout with expanding properties during reaction. The cured product creates a compression seal of varying flexibility.

Polyurethane foam resin often utilizes an activator or accelerator. Resin and activator are mixed before they are injected. Polyurethane resins are also available in two component chemical cure variants. No moisture needed.

Polyurethanes are extremely versatile. Their chemical and physical properties vary to suit the needs of specific applications and jobsite conditions.

Polyurethane resins vary from rigid and strong to flexible, rubbery and soft. The initial cure time for crack injection polyurethanes is generally 1 – 10 minutes and is influenced by accelerator usage, temperature and moisture availability.

Differences in The Epoxy and Polyurethane Crack Injection Processes

Epoxy crack injections are typically performed at lower injection pressures (20-200 psi) and with surface mounted ports.

Polyurethane crack injection is often performed at higher pressures to move the expanding foam through the cracks with special injection pumps and packers installed into drilled holes.. The injected polyurethane is supposed to fill the crack through the entire thickness of the structure thereby preventing water from entering the crack.

Epoxy Crack Injection

Structural Repair – The tensile strength and compression strength of cured epoxy is typically much greater than the strength of concrete making epoxy a good choice for foundation wall structural crack repair. When tension is applied to a crack due to thermal cycling or other forces, the cured epoxy crack repair will not typically yield. Epoxy is typically rigid and not flexible.

Extended curing time allows the epoxy to penetrate the crack and fine fissures.

Dry Substrate Recommended – Epoxy typically has reduced adhesion to wet and saturated surfaces. A dry environment is desired for best results. Actively Leaking Cracks – Epoxy cannot be used for actively leaking cracks. Epoxy resin needs to be contained in a crack until cured sufficiently to achieve full strength.

Epoxy injection is performed through surface mounted ports. Moisture adversely affects the adhesive qualities of the anchoring epoxy used to glue the injection ports onto the crack. Without sufficient bond strength, the anchoring epoxy will not withstand the pressure of the injection.

Wet and Dry Applications – Polyurethane injection foams and resins can be used in adverse environments regardless of the condition of the crack and the weather. The crack can fine or wide, actively leaking, full of mud and/or mineral deposits. (Whenever possible it is advised to flush and clean out a crack prior to injection)

Water Stop and Structure Preservation – The rapid curing of polyurethane is beneficial when stopping a gushing leak. The chemical expansion of the polyurethane foam (typically 2-40 times its original volume) makes polyurethane very effective at filling voids within the concrete. Polyurethane resins and foams play an important role in preserving concrete and rebar.

Not a Structural Repair – Polyurethanes do not provide structural repairs in concrete cracks.

High injection pressures are often required to move PU foam into fine cracks and fissures.

Mechanical packers require drill holes. No matter if the crack is actively leaking, under water or the concrete is deteriorated, mechanical packers are designed to work in adverse environments.

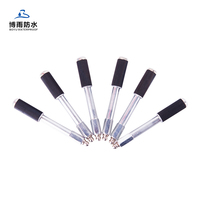

We are a waterproof company, offers Polyurethane Waterproof Coating,Injection Pump,Injection Packers, Polyurethane injection grouting and so on, Please contact us anytime.